We support hospitals with consistent access to dialysis technical experts.

With decades of service behind us, we’ve acquired an in-depth understanding of the unique needs of acute programs. Our next-generation approach defines best practices for safety, regulatory compliance, documentation, technology repair and maintenance. Our streamlined solution reduces complexity and helps hospitals operate at 100%.

Dialysis in acute settings demands being prepared at all times with up-to-date equipment maintenance. But managing needs for technicians on-demand presents a complex challenge. To ensure that no patient’s treatment is ever missed or delayed, our flexible, sustainable approach helps hospitals manage dialysis technical operations with 100% preparedness.

Strategic Partnerships Tailored to Support Your Success

To meet the diverse needs of the centers we serve, our services are provided through your choice of long-term partnerships or a la carte contracts.

Stop hiring. Get started with Bion.

You don’t have to employ full-time Biomeds for part-time needs. Bion lifts the burden of hiring and managing Biomeds off providers, so you can focus on patient-centered care.

Water System Repair & Maintenance

Machine maintenance is a critical factor in patient safety and survey preparedness. When machines break down, it can create a domino effect—delaying dialysis treatments, driving up costs, and reducing revenue. Our robust capabilities and expertise ensure that we can complete repairs and maintenance in a timely and efficient manner, to minimize any impact on your staff, patients, and budget.

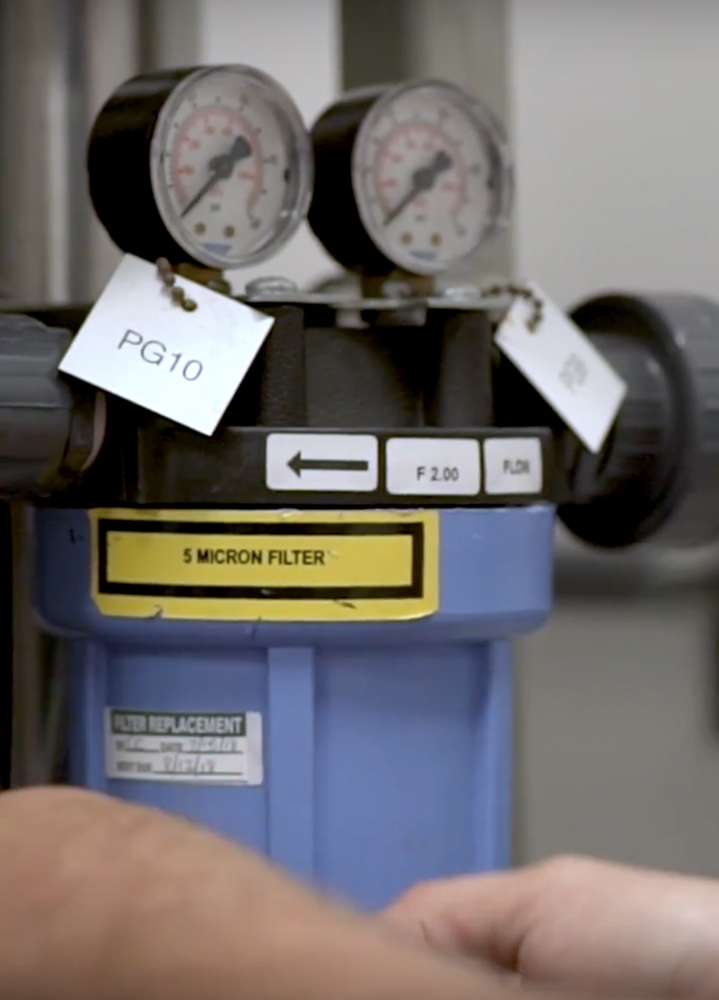

Dialysate Filter Replacement

These important ultrafilters prevent bacteria and endotoxins from reaching the patient. We replace them according to manufacturer recommendations to prevent pyrogenic reactions.

Electrical Safety Testing

AAMI standards demand annual electrical safety testing. At Bion, we test the machines during every PM to safeguard staff and patients.

Manufacturer Upgrades

Manufacturers release periodic hardware and software upgrades, which may be optional or corrective. We keep track for you, to keep your equipment up to date.

Dialysis Machine Repair & Maintenance

The heartbeat of dialysis is the water system. Through meticulous routine maintenance, we ensure patient safety and reduce risk. This includes sampling for cultures and endotoxins, and RO and distribution loop disinfections.

RO Cleaning and Disinfection

These important ultrafilters prevent bacteria and endotoxins from reaching the patient. We replace them according to manufacturer recommendations to prevent pyrogenic reactions.

Distribution System Disinfection

The distribution system distributes final purified water to its points of use. There are two ways of doing this: directly and indirectly. Direct feed systems distribute purified water from the final stage of the water system to its points of use. Indirect feed systems distribute from the final stage of the water system into a storage tank, then on to points of use. Both practices require at least monthly disinfecting to control microbial growth per CMS/AAMI regulations. The storage tank and all point-of-use locations are disinfected, including the concentrate mixing systems feed, and all dialysis machine connections.

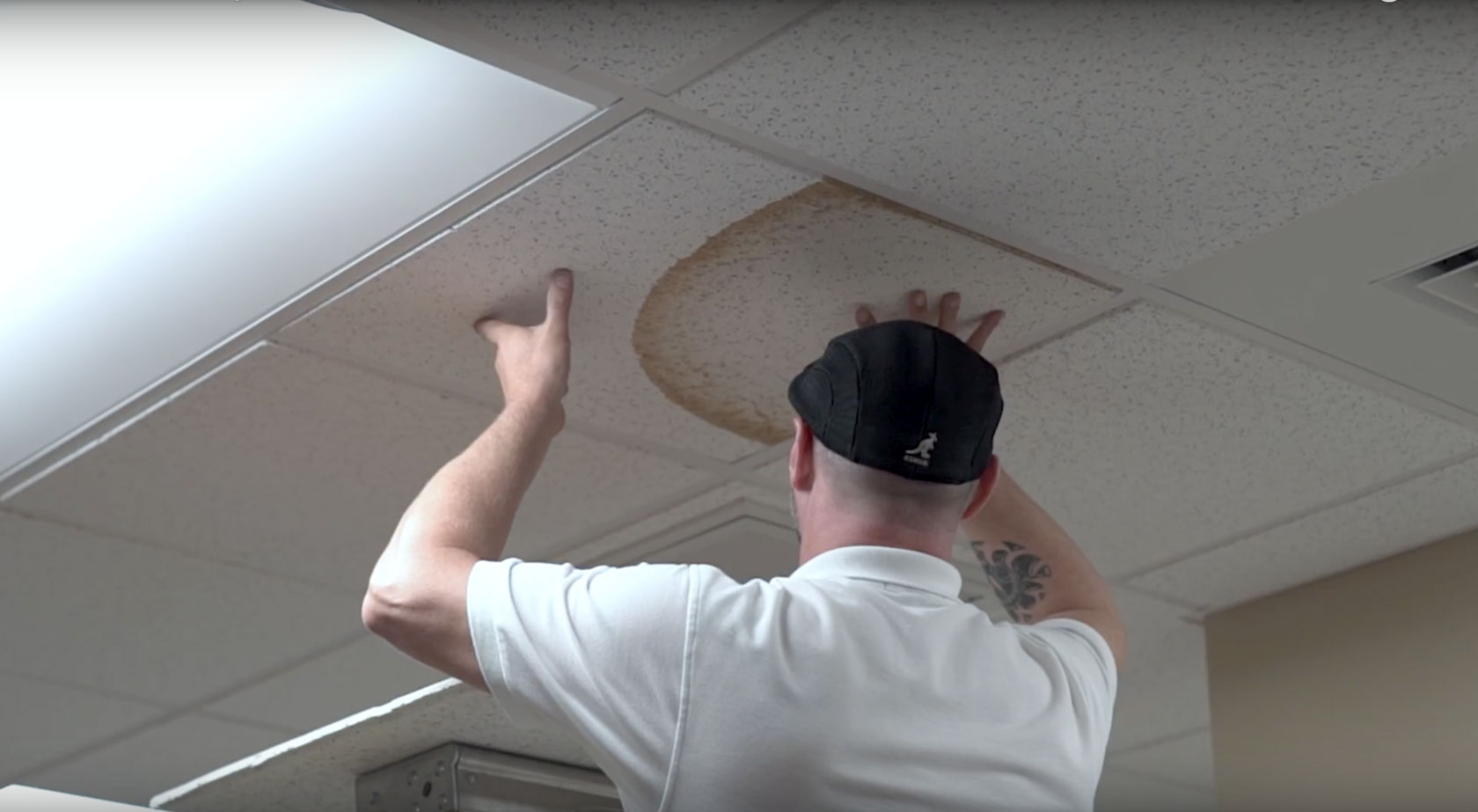

Water System Repairs

Water system components—pre-treatment tanks and their timers, flow and pressure controls, pumps, sensors, and valves—all require periodic repairs. Water systems are typically set up with PVC Schedule 80 plumbing. Working with this is a strong core competency for our Bion Technicians. Any repairs made to a major component of the RO machine or distribution system will require disinfection, AAMI analysis, and microbial growth testing each week for at least four weeks to validate the system, or until proven compliant.

Microbiology & AAMI Testing

To ensure AAMI compliance, we draw all necessary cultures and endotoxins to meet AAMI standards, and file every report in an easily-accessed cloud-based repository.

AAMI Chemical Analysis

We exceed AAMI standards, drawing chemical analysis samples quarterly to ensure patient safety and integrity of the membranes.

Cultures and Endotoxins

Cultures and endotoxins are drawn within 72 hours of disinfection to emulate ‘worst case’ conditions as defined by CMS and AAMI, to comply with regulations. These frequencies can be specified to adhere to facility policies, as well as any action plans that are in place to address problems.

Technical Audits and QAPI Meeting Reports

Routine Technical Audits keep facilities survey-ready, and our Monthly Technical Reports provide all required documentation for the QAPI program. Our experts are well-equipped to predict what’s needed to adhere to all standards and regulations, ensuring that your dialysis equipment, and your facility stay 100% in compliance with CMS and AAMI. We provide monthly, quarterly, and annual reports, which are easily accessible in a cloud-based repository. In addition, we can represent the clinic onsite during QAPI meetings and state surveys.